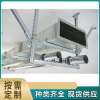

热风回流焊回流焊厂家大型回流焊价格:1.00元/台 最小起订量:1 台 供货总量:500 台 发货期限:自买家付款之日起30天内发货 有效期至:长期有效

产品特点:

1、Windows 视窗操作界面,德国西门子PLC+液晶电脑控制系统,具有极高保障功能.

2、 微循环加热方式,可实现较大的热风交换量,拥有极高的热交换率,可降低温区设置温度,对受热元件起保护作用,特别适合于无铅焊接.

3、微循环加热方式,垂直吹风垂直收风,可解决一般回流焊使用导轨焊接时的死角难题.

4、 微循环加热方式,,收风口离吹风口最近,可有效防止PCB板受热时的风流影响,达到最高的重复加热精度.

5、确保加热过程的超稳定性,并拥有全行业最小的△t偏差,尤其针对高难度焊接工艺.

6、来自国际技术的急冷却系统,采用放大镜式集中高效急冷,冷却速度可达3.5~6℃/秒,管理十分方便.

7、同步齿条、导轨传输机构,确保导轨调宽精确及高使用寿命.

8、电脑控制自动润滑系统,可通过电脑设置加油时间及加油量,自动润滑传输链条.

9、集成控制窗口,电脑开关、电动调宽、测试曲线、打印曲线及传输数据均可方便操作,设计人性化.

10、曲线测试及曲线分析功能可分析最高温度、区间段时间、升温及降温速度,方便工艺调节.

11、拥有密码管理的操作系统,防止无关人员改动工艺参数,操作记录管理可追溯工艺参数的改动过程,方便改善管理.

12、循环风速连续可调,应对各类焊接工艺.

13、松香回收系统,松香定向流动至储存瓶中,更换清理十分方便.采用不锈钢管传送废气,终身免维护.

14、发热丝+变频运风+微循环,拥有极高的热交换率,BGA底部与PCB板之间产生的温差△t极小,最符合无铅制程严格的要求,尤其针对高难度焊接要求的无铅产品.

Product features

1, Windows, Windows operating interface, Germany's Siemens PLC + LCD computer control system, with functions of high security.

2, microcirculation heating mode, which can realize large hot air exchange capacity, has a very high heat exchange rate, can decrease the temperature set temperature, the heating element protection, especially suitable for lead-free soldering.

3, microcirculation heating mode, vertical flow vertical ShouFeng, can solve the reflow soldering commonly use guide rail welding corner problem.

4, microcirculation heating mode, and tuyere nearest blowing mouth, which can effectively prevent PCB

when heated wind influence, to the repeated heating of the highest accuracy.

5, to ensure the heating process of super stability, and has the industry's smallest delta t deviation, especially for difficult welding process.

6, cooling system, from the international technology USES a magnifying glass type efficient quenching, the cooling speed can reach 3.5 ~ 6 ℃ / s, management is very convenient.

7, synchronous rack and guide rail transport organization, ensure the service life of the slideway adjustable high precision and wide.

8 automatic lubrication system, computer control, can be set up by computer come on time and amount, automatic lubrication transmission chain.

9, integrated control window, the computer switch, electric adjustable width and test curve, print, curve and transmission data are easy to operation, the humanized design.

10, test curve and curve function can analysis the highest temperature, interval time, temperature and cooling speed, convenient adjustment process.

11, a password management operation system, to prevent irrelevant personnel changes, process parameters, operation records management traceability process parameters change process, convenient to improve management.

12, circulation wind speed adjustable, dealing with all kinds of welding process.

13, rosin recovery system, directional flow to store the bottle of rosin to replace cleaning is very convenient. Stainless steel pipe transmission exhaust, free maintenance for life.

14, heat wire + frequency conversion + microcirculation, wind has extremely high heat exchange rate, at the bottom of the BGA and the temperature difference between the PCB delta t, most conforms to the strict lead-free process requirements, especially for difficult product of lead-free welding requirements.

F系列回流焊技术参数 Reflow soldering technology parameters

Series 系列 F系列(通用机)

Model 型号 CY-F820 CY-F1020

加热部分参数 The heating part parameters

Heating area number 加热区数量 上8/下8 上10/下10

Number of cooling zone 冷却区数量 上Top2/下Bottom2

运输部分参数 Transportation part parameters

PCB maximum width PCB最大宽度 导轨式350mm

Guide the wide range 运输导轨调宽范围 50-350mm

Transport direction 运输方向 L→R(R→L)

Guide rail fixed way 运输导轨固定方式 前端/Front(选配:后端固定)

Conveyor belt speed 运输带高度 网带900±20mm,链条900±20mm

Transmission way 传送方式 链传动+网传动

Conveyor belt speed 运输带速度 300-2000mm/Min

控制部分参数 Control part of the parameter

The power supply 电源 5线3相380V 50/60Hz

Start the power 启动功率 38Kw 45Kw

Normal work consumed power 正常工作消耗功率 Approx.8Kw Approx.8.5Kw

Heating up time 升温时间 约20分钟

The temperature control range 温度控制范围 室温-350℃Room Temper ature-350℃

Temperature control mode 温度控制方式 全电脑PID闭环控制,SSR驱动

The whole machine control mode 整机控制方式 电脑+PLC

The temperature control precision 温度控制精度 ±1℃

The deviation of PCB temperature distribution PCB板温度分布偏差 ±1-2℃

Cooling way 冷却方式 空气机:风冷, 氮气机:水冷

Abnormal alarm 异常报警 温度异常(恒温后超高或超低)

Three color light 三色灯指示 三色信号灯:黄—升温;绿—恒温;红—异常

机体参数 The body parameter

Weight 重量 Approx.1600Kg Approx.1800Kg

Installation dimensions(mm) 外型尺寸(mm) L5050×W1320×H1450 L6050×W1320×H1450

Exhaust air requirements 排风量要求 10立方/min 2通道∮180MM

氮气部分(选项) Nitrogen part (option)

Nitrogen protection device 氮气保护装置 氮气流量20-30立方/小时 氧气浓度500-800PPM

The external water cooling system 外置水冷却系统 功率3P 制冷速度≧6℃/sec

本文引用地址:http://www.worldmetal.cn/sell/show-1359147-1.html

以上"诚远无铅热风回流焊CY-F820"信息由企业自行提供,该企业负责信息内容的真实性、准确性和合法性。本网对此不承担任何保证责任。

以上"诚远无铅热风回流焊CY-F820"信息由企业自行提供,该企业负责信息内容的真实性、准确性和合法性。本网对此不承担任何保证责任。